2014 Aluminum Plates

Introduction to 2014 Aluminum Plates

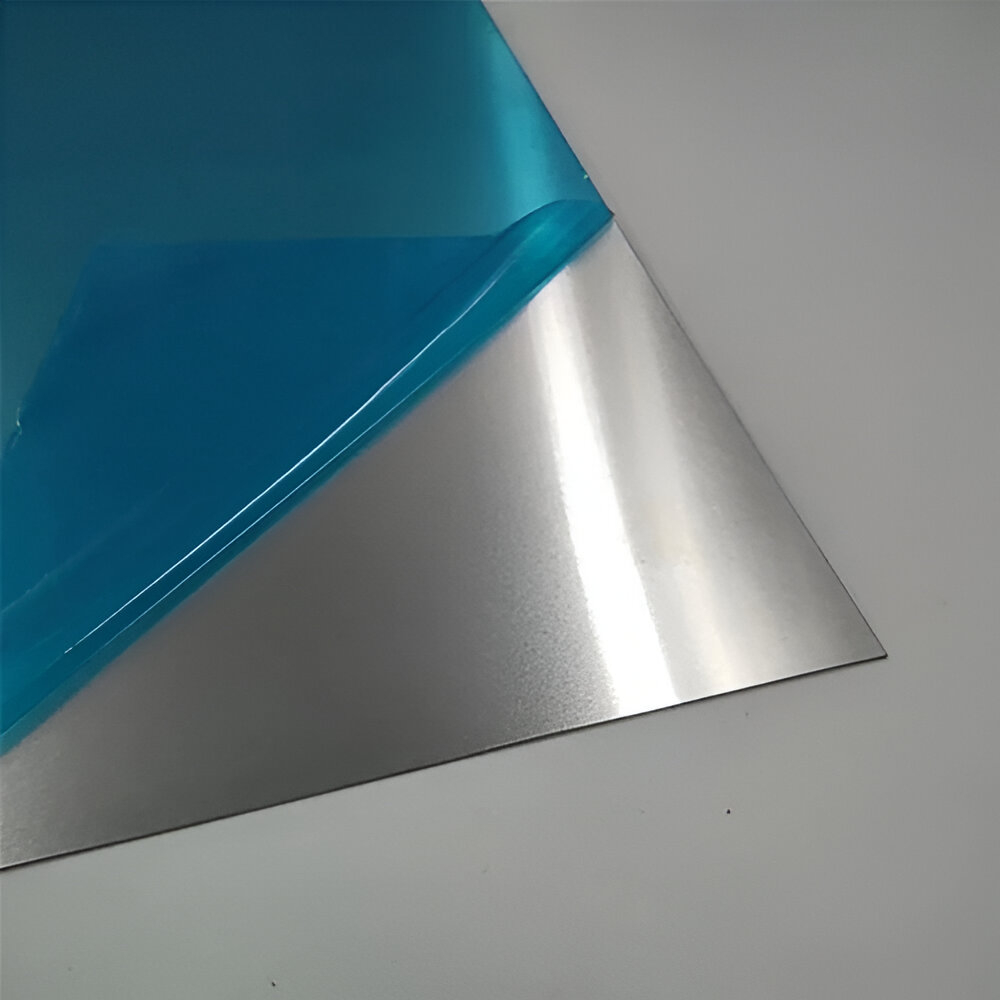

2014 Aluminum Plates are among the most widely used aluminum alloys, known for their exceptional strength, high hardness, and excellent machinability. These plates are primarily used in aerospace, automotive, and structural applications where strength and durability are critical. As a high-strength aluminum alloy, 2014 aluminum plates offer superior resistance to fatigue and stress, making them an excellent choice for heavy-duty applications.

Related

Products

At Metalco Global, we are a leading 2014 Aluminum Plates Manufacturer and supplier, offering premium-quality products that meet international standards. Our aluminium plates are available in various thicknesses, sizes, and finishes to cater to the diverse needs of industries worldwide

Key Features of 2014 Aluminum Plates

- High Strength and Durability – 2014 aluminum is one of the strongest aluminum alloys, making it ideal for applications that require high mechanical strength.

- Excellent Machinability – This alloy is easy to machine, reducing production time and costs.

- Good Corrosion Resistance – When treated and coated properly, 2014 aluminum exhibits resistance to corrosion in harsh environments.

- Superior Fatigue Resistance – Suitable for applications exposed to repetitive stress and pressure.

- Heat Treatable – This alloy can be heat-treated to improve mechanical properties.

Applications of 2014 Aluminum Plates

Due to their impressive strength-to-weight ratio and fatigue resistance, 2014 aluminum plates are widely used in various industries:

1. Aerospace Industry

- Aircraft fuselage components

- Structural aerospace frames

- Landing gear parts

2. Automotive Industry

- High-performance vehicle components

- Suspension systems

- Engine parts

3. Military and Defense

- Armored vehicle parts

- Missile components

- Military-grade structures

4. Marine Industry

- Boat hulls and decks

- Structural reinforcements

5. Construction and Structural Engineering

- Bridges and load-bearing structures

- Heavy machinery parts

Chemical Composition of 2014 Aluminum Plates

| Chemical Element | % Present |

|---|---|

| Silicon (Si) | 0.50 – 0.90 |

| Iron (Fe) | 0.0 – 0.50 |

| Copper (Cu) | 3.90 – 5.00 |

| Zinc (Zn) | 0.0 – 0.25 |

| Manganese (Mn) | 0.40 – 1.20 |

| Magnesium (Mg) | 0.20 – 0.80 |

| Titanium (Ti) | 0.0 – 0.15 |

| Others (Total) | 0.0 – 0.15 |

| Chromium (Cr) | 0.0 – 0.10 |

| Nickel (Ni) | 0.0 – 0.10 |

| Other (Each) | 0.0 – 0.05 |

| Titanium + Zirconium (Ti+Zr) | 0.0 – 0.20 |

| Aluminium (Al) | Balance |

Mechanical Properties Of Aluminium Alloy 2014 Plates

| Mechanical Property | Value |

|---|---|

| Tensile Strength | 440 Min MPa |

| Proof Stress | 390 Min MPa |

| Hardness Brinell | 133 HB |

Mechanical Properties Of Aluminium Alloy 2014 Plates Physical Properties Of Aluminium Alloy 2014 Plates

| Physical Property | Value |

|---|---|

| Density | 2.82 g/cm³ |

| Modulus of Elasticity | 71 GPa |

| Electrical Resistivity | 0.045 x10^-6 Ω .m |

| Thermal Conductivity | 138 W/m.K |

| Thermal Expansion | 23 x10^-6 /K |

| Melting Point | 535 °C |

Why Choose Metalco Global for 2014 Aluminum Plates?

As a trusted 2014 Aluminum Plates Manufacturer and 2014 Aluminum Plates Supplier, Metalco Global ensures superior quality and reliability. Here’s why we are the best choice:

1. Premium-Quality Materials

We source high-grade aluminum to manufacture our 2014 aluminum plates, ensuring outstanding durability and performance.

2. Customized Solutions

We offer customized thickness, dimensions, and finishes to meet the specific requirements of various industries.

3. Competitive Pricing

Our direct manufacturing approach helps in keeping costs low while maintaining high-quality standards.

4. Global Supply Chain

With a robust supply network, we deliver 2014 aluminum plates efficiently to clients across different regions.

5. Compliance with Industry Standards

Our products adhere to international quality and safety standards, ensuring reliability in critical applications.

Manufacturing Process of 2014 Aluminum Plates

Our manufacturing process follows strict quality control measures:

- Raw Material Selection – We use high-purity aluminum and alloying elements.

- Melting and Casting – The raw materials are melted and cast into slabs or billets.

- Rolling Process – The cast slabs are hot-rolled to achieve the desired thickness.

- Heat Treatment – The plates undergo heat treatment to enhance mechanical properties.

- Surface Finishing – Various finishing techniques like anodizing and powder coating are applied for corrosion resistance.

- Quality Testing – Every plate is tested for strength, hardness, and dimensional accuracy.

Conclusion

2014 Aluminum Plates are a top choice for industries requiring high-strength materials with excellent machinability. Whether you need aluminum plates for aerospace, automotive, military, or structural applications, Metalco Global is your trusted 2014 Aluminum Plates Manufacturer and 2014 Aluminum Plates Supplier.

We offer premium-grade aluminum plates tailored to meet your specifications at competitive prices. Contact us today to get a quote or to learn more about our extensive range of aluminum products.

Frequently Asked Questions

2014 aluminium plates are valued for their impressive tensile strength, ease of machining, and reliable performance under repeated stress or load They are ideal for heavy-duty structural components and aerospace applications where strength is critical.

2014 aluminium plates offer moderate corrosion resistance. They are often treated with protective coatings or anodizing when used in corrosive environments.

2014 aluminium plates are commonly used in aerospace components, structural parts, automotive applications, and military-grade equipment due to their strength and durability.