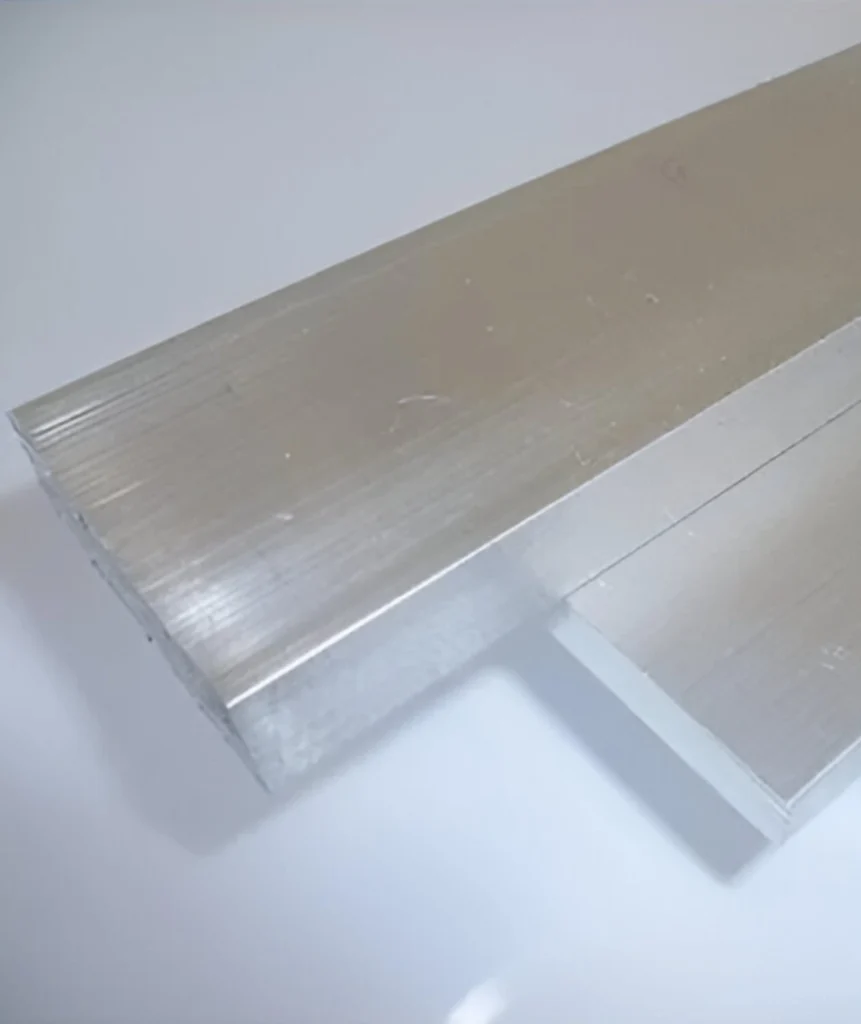

Aluminium 1050 Flat Bars: Precision, Purity, and Performance

Aluminium 1060 flat bars are known for their high purity, excellent corrosion resistance, and outstanding workability. These characteristics make them ideal for a wide range of applications that require superior formability, conductivity, and aesthetic appeal.

At Metalco Global, we deliver Aluminium 1060 flat bars that meet the demands of industries such as electrical, architectural, and general fabrication. Precision-processed and quality-assured, our flat bars offer exceptional reliability for both functional and decorative purposes.

Related

Products

At Metalco Global, we take pride in offering superior-quality Aluminium 1050 flat bars tailored to the specific needs of our clients across sectors such as electrical engineering, food processing, architectural design, and chemical manufacturing.

What is Aluminium 1050?

Aluminium 1050 is recognized for high-purity aluminium alloys. With a minimum aluminium content of 99.5%, this alloy delivers reliable chemical stability, excellent reflectivity, and unmatched resistance to atmospheric corrosion. It is ideal for environments where cleanliness, conductivity, and resistance to oxidation are critical.

While Aluminium 1050 may not possess high tensile strength compared to alloyed grades, it compensates with exceptional flexibility and a surface quality that makes it highly sought-after for finishing operations such as polishing or anodizing.

Characteristics of Aluminium 1050 Flat Bars

High Purity

Containing more than 99.5% aluminium, this grade ensures high corrosion resistance and minimal contamination, making it ideal for sensitive industrial environments.

Excellent Electrical Conductivity

Aluminium 1050 is often used in electrical components due to its high conductivity, making it an efficient and economical replacement for copper in many applications.

Superior Thermal Conductivity

This alloy is also known for its outstanding heat conductivity, making it a great material for heat exchangers, radiators, and cooling systems.

Exceptional Formability

Due to its softness and malleability, Aluminium 1050 flat bars can be easily bent, formed, and shaped without the risk of cracking—ideal for detailed custom work.

Corrosion Resistance

It performs exceptionally well in humid or mildly acidic environments, providing longevity in marine, architectural, and industrial applications.

Lightweight & Durable

Despite being lightweight, these flat bars offer excellent surface durability, making them a practical choice for non-load-bearing applications.

Applications of Aluminium 1050 Flat Bars

Aluminium 1050 flat bars are used extensively across industries for both functional and aesthetic purposes. Their combination of low weight, high workability, and superior resistance to environmental factors makes them incredibly versatile.

Electrical Industry

Used in busbars, switchboards, and conductors, Aluminium 1050 flat bars provide excellent electrical performance and reduce weight and cost.

Food & Beverage Industry

Being non-toxic and highly resistant to corrosion, this material is ideal for food processing equipment, utensils, and storage solutions that meet hygiene standards.

Signage and Display

Its smooth surface finish and corrosion resistance make it perfect for signboards, display units, and architectural claddings.

Chemical and Pharmaceutical Industry

Its resistance to certain chemicals makes it suitable for storage tanks, reactors, and piping in chemical plants and pharmaceutical units.

HVAC and Heat Exchangers

Thanks to its thermal conductivity, Aluminium 1050 flat bars are used in heat exchanger systems, radiators, and air conditioning components.

Architectural Applications

Used in doors, window frames, curtain walls, and interior design, its formability and surface finish help meet both functional and design criteria.

Fabrication and Workability

One of the biggest strengths of Aluminium 1050 flat bars lies in how easily they can be fabricated. Whether it’s cutting, bending, machining, or polishing, these bars adapt well to a range of fabrication techniques. Their soft texture allows for intricate shaping and forming without the need for expensive tools or heat treatment.

Moreover, the alloy is weldable using conventional methods, particularly through gas, TIG, or MIG welding processes. For industries that require frequent customization and quick prototyping, Aluminium 1050 offers a low-risk, high-reward solution.

Sustainability and Environmental Benefits

Aluminium 1050 is 100% recyclable without any loss in its natural properties, making it a sustainable option for industries aiming to minimize their environmental impact. Manufacturing products with recycled aluminium consumes only a fraction of the energy used for producing primary aluminium, which significantly reduces greenhouse gas emissions.

By choosing Aluminium 1050 flat bars, you’re not only optimizing your production but also contributing to a more circular and eco-conscious economy.

Quality Assurance at Metalco Global

At Metalco Global, quality is at the heart of everything we do. Each batch of Aluminium 1050 flat bars undergoes rigorous quality checks to ensure they meet international industry standards. Our in-house experts use precision equipment to verify dimensional accuracy, surface integrity, and consistency in alloy composition.

We offer our products in a wide range of lengths, widths, and thicknesses. Whether you’re handling small-scale projects or bulk industrial requirements, we provide:

- Custom-cut lengths

- Deburred edges

- High-quality surface finish

- Packaging for safe delivery

Our advanced logistics and supply chain enable us to serve clients across the globe quickly and efficiently.

Ideal for Custom Engineering Projects

The flexibility of Aluminium 1050 makes it ideal for prototyping and specialized projects. Whether you’re an architect seeking sustainable materials or an OEM manufacturer producing parts for sensitive equipment, Aluminium 1050 flat bars provide design freedom with outstanding reliability.

From cleanroom components to artistic installations, Aluminium 1050 serves a broad range of custom fabrication needs.

Industries That Rely on Aluminium 1050 Flat Bars

- Electrical and Electronics

- Pharmaceutical and Medical

- Food & Beverage

- HVAC Systems

- Architectural and Interior Design

- Signage and Advertising

- Packaging and Storage Solutions

No matter your industry, Aluminium 1050 flat bars offer material integrity, versatility, and cost-efficiency that few other metals can match.

Final Thoughts

Aluminium 1050 flat bars are a smart choice for industries that demand high purity, corrosion resistance, and exceptional formability. Whether you’re designing lightweight electrical components, building food-grade processing units, or constructing durable signage, this alloy delivers dependable results every time.

At Metalco Global, we’re committed to providing premium Aluminium 1050 flat bars that meet your exact requirements. Our team ensures consistent quality, fast delivery, and the technical know-how to support your projects from start to finish.