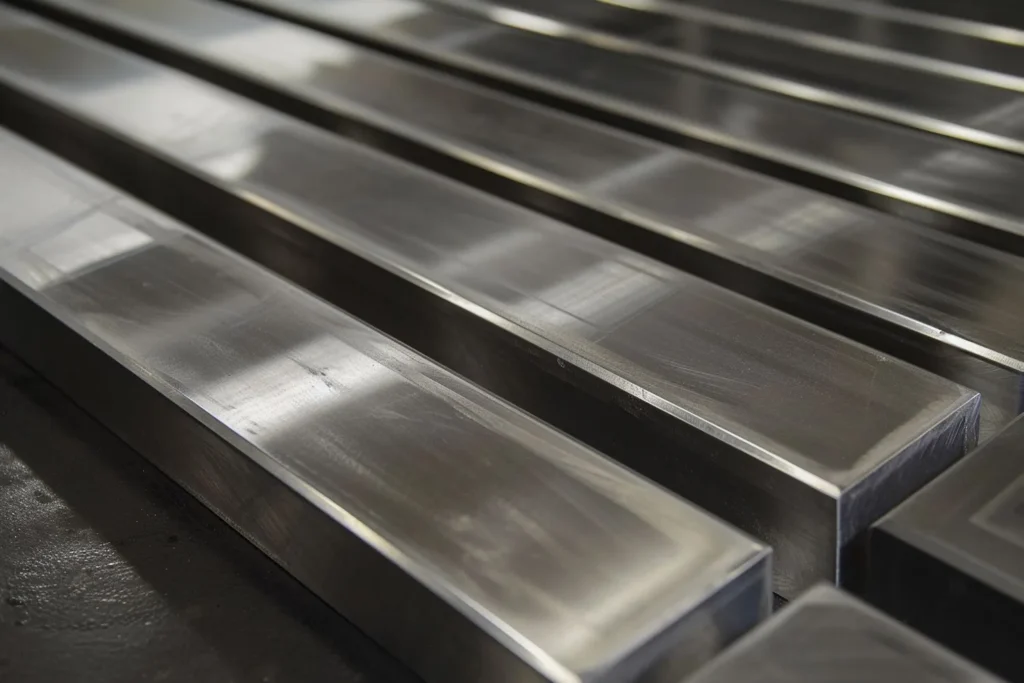

1100 Aluminium Square Bar

Aluminium 1100 Square Bar

Metalco Global Extrusions LLP is a trusted name in the aluminium industry, offering a wide range of premium-quality extruded and rolled aluminium products. Among our most sought-after offerings, the Aluminium 1100 Square Bars stand out for their superior purity, corrosion resistance, and excellent formability. As one of the softest yet most workable grades of aluminium, Alloy 1100 is ideal for applications requiring high thermal conductivity, excellent finishing, and outstanding fabrication potential.

At Metalco Global, we manufacture Aluminium 1100 Square Bars using advanced extrusion technology and precision engineering. Our bars are crafted to deliver consistent strength, perfect dimensional accuracy, and smooth surfaces suitable for anodizing, polishing, and various surface treatments. Designed to meet international standards, our products are trusted by clients across the globe for their reliability and versatility in both commercial and industrial applications.

Related

Products

About Aluminium 1100 Square Bars

Aluminium 1100 Square Bars is one of the most widely used alloys for general fabrication and architectural applications due to its superior corrosion resistance, thermal conductivity, and reflectivity. The alloy also offers excellent weldability and workability, making it an ideal choice for operations such as spinning, deep drawing, and forming.

Unlike high-strength alloys that prioritize tensile strength over formability, Alloy 1100 focuses on ductility, purity, and performance consistency. It can be cold-worked extensively without cracking, ensuring that manufacturers achieve precise shapes and sizes without compromising the material’s structural integrity.

Key Features and Benefits of Aluminium 1100 Square Bars

At Metalco Global Extrusions LLP, we ensure our Aluminium 1100 Square Bars deliver exceptional mechanical and physical properties. Some of the main features include:

1. Excellent Corrosion Resistance

Aluminium 1100 exhibits outstanding resistance to atmospheric corrosion, especially in marine and chemical environments. This makes it highly suitable for outdoor structures, food processing, and marine fittings.

2. High Thermal and Electrical Conductivity

This alloy has excellent thermal and electrical conductivity, making it a preferred choice for electrical components, heat exchangers, and thermal transfer systems.

3. Superior Formability and Workability

Aluminium 1100 can be easily formed, bent, drawn, and machined, making it perfect for applications that require complex shaping and fine detailing.

4. Lightweight and Cost-Effective

Its low density and competitive pricing make Aluminium 1100 an economical alternative to other non-ferrous metals, especially in projects prioritizing lightweight strength.

Applications of Aluminium 1100 Square Bars

The versatility and mechanical properties of Aluminium 1100 Square Bars make them a key material across multiple industries:

Aerospace and Aviation

Used in non-structural components such as covers, brackets, and decorative trims where weight reduction and corrosion resistance are essential.

Electrical Industry

Aluminium 1100’s excellent electrical conductivity makes it suitable for bus bars, conductors, and terminals.

Chemical and Food Processing Equipment

Due to its resistance to chemicals and non-toxicity, this alloy is widely used in tanks, piping, and utensils in food and beverage manufacturing.

Thermal Applications

Commonly used in heat exchangers, cooling systems, and radiators where efficient heat transfer is required.

Marine and Offshore Structures

Resists corrosion in marine environments, making it ideal for boat fittings, hull components, and dock equipment.

Manufacturing Excellence at Metalco Global Extrusions LLP

At Metalco Global Extrusions LLP, quality is not just a process — it’s our promise. Our state-of-the-art manufacturing facilities employ the latest extrusion technologies and advanced quality control systems to ensure that each Aluminium 1100 Square Bar meets international standards.

Our Production Process Includes:

Raw Material Selection – Using only certified primary aluminium billets.

Homogenization and Heating – Ensuring uniform grain structure and mechanical consistency.

Extrusion and Cooling – Using modern presses for tight tolerance and precise surface finish.

Cutting and Machining – Dimensionally accurate cutting and optional CNC machining services.

Quality Inspection – Rigorous checks for mechanical strength, surface finish, and dimensional accuracy.

Packaging and Dispatch – Secure packaging to prevent corrosion and transit damage during global shipping.

Our quality assurance team monitors every stage of production — from billet casting to final inspection — ensuring that clients receive only the best.

Conclusion

The Aluminium 1100 Square Bars from Metalco Global Extrusions LLP are the embodiment of purity, performance, and precision. Designed to cater to industries that demand reliability and durability, these bars are the preferred choice for manufacturers and engineers across aerospace, electrical, marine, and construction sectors.

Our dedication to quality, innovation, and customer satisfaction sets us apart as one of the most trusted aluminium extrusion manufacturers in India and abroad. Whether your requirements involve custom dimensions, specific temper grades, or special surface finishes, Metalco Global ensures world-class aluminium solutions tailored to your needs.

Partner with Metalco Global Extrusions LLP for superior aluminium products that redefine performance, quality, and trust — where engineering excellence meets global standards.