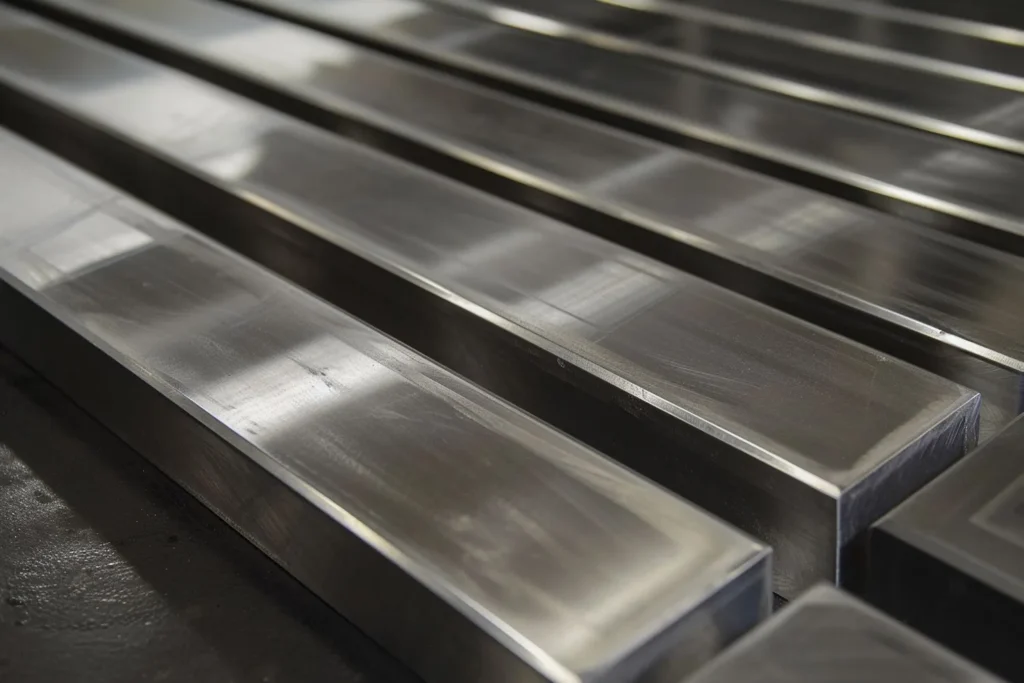

2024 Aluminium Square Bars

2024 Aluminium Square Bars – Precision & Performance from Metalco Extrusions Global LLP

As one of the leading 2024 Aluminium Square Bars Manufacturers and 2024 Aluminium Square Bars Suppliers, Metalco Extrusions Global LLP offers premium quality square bars in alloy 2024, engineered for high strength, fatigue-resistance and demanding industrial applications. Our commitment to full-spectrum product support—from chemical composition to finishing—ensures you receive reliable material for critical applications.

Related

Products

Why choose 2024 Aluminium Square Bars?

The alloy commonly referred to as 2024 (UNS A92024, AlCu4Mg1) is a high-strength 2xxx-series aluminium alloy with copper as the major alloying element. Some of the key advantages that make 2024 square bars especially attractive:

High strength-to-weight ratio: 2024 alloy exhibits superior strength compared to many other aluminium alloys, making it ideal for structural components in aerospace, transport and heavy engineering.

Good fatigue resistance: Its ability to perform under cyclical stresses lends it to applications where durability matters.

Excellent machinability (in the right temper): Machining and finishing of square bars made of this alloy is efficient when proper tooling is used.

Versatile finishing and processing: 2024 square bars can be supplied in various tempers, finishes and sizes to meet diverse application needs.

That said, it’s worth noting the alloy’s relative corrosion resistance is less than certain 5xxx or 6xxx-series alloys. In many applications it is clad or surface-treated to improve corrosion behaviour.

Our Capabilities – From Manufacturer to Supplier

At Metalco Extrusions Global LLP, as a trusted 2024 Aluminium Square Bars Manufacturer and 2024 Aluminium Square Bars Supplier, we cover the full lifecycle of supply:

• Raw-material procurement & metallurgy

We source high-quality ingots and apply rigorous metallurgical control for the 2024 alloy chemistry, ensuring consistency in copper, magnesium, manganese and other elements as per relevant standards. For example typical composition limits: Cu 3.8-4.9 %, Mg 1.2-1.8 %, Mn 0.3-0.9 %, Si & Fe <0.5%.

• Forming and extrusion / rolling

We manufacture square bars via hot-rolled, cold-finished or extruded routes depending on customer requirements. We can provide square section sizes from small cross-sections up to large dimensions, temper conditions like T3, T6, T651 etc.

• Finishing & certification

Surface finishes: mill-bright, polished, sand-blasted, hair-line, checkered or embossed. Finishing treatments such as anodising or protective coatings can be applied. Material test certificates, chemical & mechanical test reports are available.

• Supply chain & logistics

As a full-scale 2024 Aluminium Square Bars Supplier, we stock ready-to-ship inventory, offer custom length cutting, bundling, packaging (wooden crates, steel-banded bundles) and export globally. Our customer service supports everything from enquiry to delivery.

Specifications & Standards

Being a reputable manufacturer and supplier, we adhere to international standards for alloy 2024 square bars. Some of the commonly referenced specifications include:

ASTM B221 / ASME SB221 – Aluminum and Aluminum-Alloy Extruded Bars, Rods.

ASTM B211 / ASME SB211 – Aluminum and Aluminum-Alloy Bars, Rods, and Wire (rolled or cold-finished)

AMS/ISO equivalents and European standards such as DIN 3.1355 (for 2024 alloy)

Typical sizes and conditions:

Cross-section: square shapes from as small as 5 mm up to 500 mm or more depending on customer needs.

Lengths: from 100 mm up to 3000 mm or more, depending on application.

Tempers: T3, T4, T5, T6, T651, T6511 etc.

Finishes: Bright, black, polished, hair-line, checkered, PVC coated, colour coated, etc.