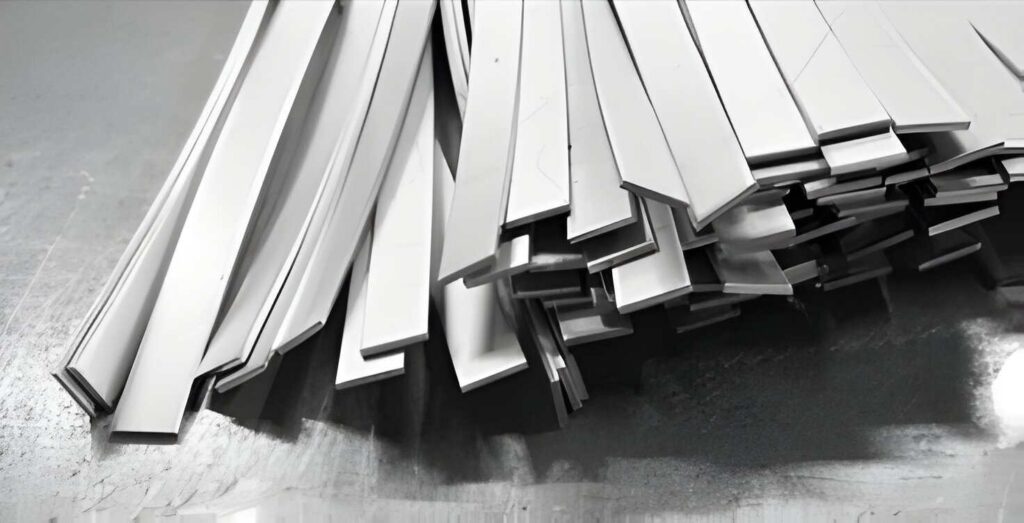

Aluminium 5086 Flat Bars

Aluminium 5086 Flat Bar – Premium Solution for Critical Structural Applications

When you’re seeking high-performance flat bar solutions, the Aluminium 5086 flat bar stands out as a robust and versatile choice. At Metalco Extrusions Global LLP, we offer top-quality 5086 Aluminium flat bar in a wide range of dimensions, tempers and finishes — and we pride ourselves among the leading 5086 Aluminium flat bar suppliers in India and globally.

Why Choose 5086 Aluminium Flat Bar?

The alloy designation 5086 (also known as UNS A95086) is part of the 5xxx series aluminium-magnesium alloys. It is characterized by excellent corrosion resistance, particularly in marine environments, and has good weldability and moderate strength.

Because these bars are designed to be durable, formable, and reliable, they are widely used where flat bar profiles are required for structural or marine applications.

Related

Products

By choosing the Aluminium 5086 flat bar you benefit from:

A material that has high durability and long service life, especially in harsh environments.

Excellent formability and versatility: the flat bar shape means you can easily incorporate it into structural frames, platforms, racks, frames and sheet-metal assemblies.

Good machinability and fabrication characteristics, especially in the strain-hardened tempers.

Corrosion resistance in salt water and marine conditions, making it ideal for offshore, shipbuilding and coastal environments.

Aluminium 5086 Flat Bars Chemical Composition

| Alloy | Si | Fe | Cu | Mn | Mg | Cr | Zn | Ti | Others, each | Others, total | Al |

| 5086 | 0.4 | 0.5 | 0.1 | 0.20-0.70 | 3.5-4.5 | 0.05-0.25 | 0.25 | 0.15 | 0.05 | 0.15 | Balance |

|---|

Mechanical Properties of Aluminum 5086 Flat Bars

| Proof Stress | Tensile Strength | Hardness Brinell | Elongation |

| 125 Min MPa | 275 – 350 MPa | 75 HB | 12 Min % |

Key Characteristics of Our 5086 Aluminium Flat Bar

As experienced 5086 Aluminium flat bar suppliers, we provide flat bars manufactured to global industry standards, with full adherence to specification, mechanical testing and traceability. Typical specifications include:

Conforming standards: ASTM B221, B211, B565, B316, AMS 4121, or equivalent.

Tempers: O, H12, H14, H16, H18, H19, H22, H24, H26, H28, H32, H34, H36, H38, H111, H112, H114, H116, H321 etc.

Lengths: From 100 mm up to 3,000 mm or more, or cut-to-length per client requirement.

Sizes: Flat bar widths and thicknesses ranging from approximately 5 mm up to 500 mm (or more) depending on application.

Finishes: Bright, polished or black (depending on customer specification).

Chemical composition (typical): Si ≤0.4 %, Fe ≤0.5 %, Cu ≤0.1 %, Mn 0.2-0.7 %, Mg 3.5-4.5 %, Cr 0.05-0.25 %, Zn 0.15 %, Ti 0.05 %. Balance aluminium.

Mechanical properties (typical): Proof stress min ~125 MPa, tensile strength ~275-350 MPa, Brinell hardness ~75 HB, elongation min ~12 %. These characteristics ensure the 5086 Aluminium flat bar is well suited for demanding structural applications.

Applications of Aluminium 5086 Flat Bar

Thanks to its mechanical and corrosion-resistance properties, the Aluminium 5086 flat bar is used extensively across industrial sectors. Typical application zones include:

Marine & offshore structures: platforms, ship decks, hull stiffeners, gangways and framing parts. The alloy’s ability to resist seawater corrosion and retain strength after welding makes it a preferred option.

Transportation equipment: chassis frames, bus/truck components, railcar parts where lightweight and corrosion-resistance are key.

Structural & architectural applications: load bearing frames, long span members, facade supports, where the flat bar form factor gives design flexibility.

Pressure vessels and tanks: for chemical, petrochemical and cryogenic applications, where corrosion resistance and weldability matter.

General engineering and fabrication: brackets, gussets, tie-bars, structural stiffeners, machine bases, where flat bar geometry is required, and the high performance of 5086 offers a competitive edge.

By opting for a high-quality supply of 5086 Aluminium flat bar, you ensure reliability, consistent performance and longer life of structural assemblies, especially in challenging environments.

Why Choose Us Among 5086 Aluminium Flat Bar Suppliers?

As a leading supplier, we differentiate ourselves by:

End-to-end quality assurance: We perform a wide range of tests including flaring, flattening, macro/micro structure, hydrostatic, radiography, ultrasonic, chemical, hardness, PMI and impact tests.

Extensive inventory & custom sizes: From small widths to large sections, short lengths to long runs, we cater to custom requirements of width, thickness, length, temper and finish.

Global export footprint: We supply to major Indian metro cities (Mumbai, Bengaluru, Chennai, Delhi, etc.) as well as to international markets including Middle East, Southeast Asia, Europe and North America.

Technical support & value-added services: We assist in material selection, grade/temper advice, cutting to length, packaging for export, on-time logistics.

Competitive pricing & reliability: Our strong manufacturing and supply chain infrastructure enables cost-effective delivery and reliable material availability.

When you engage with us for your Aluminium 5086 flat bar requirement, you benefit not just from product performance but also from service excellence.